Introduction

Pedestrian safety remains one of the most critical challenges in modern transportation engineering. While global road fatalities are gradually declining, the number of pedestrian deaths continues to rise. According to the U.S. Governors Highway Safety Association (GHSA), 7,508 pedestrians lost their lives in 2022 — the highest figure since 1981. Similarly, in Vietnam, over 9,000 people were killed and 11,000 injured in road accidents between 2022 and mid-2023.

Addressing this issue, researchers from Van Lang University and Ho Chi Minh City University of Technical Education conducted an in-depth study on the optimization of car front bumpers to minimize lower limb injuries in pedestrian collisions.

Key Research Objectives

The study aims to analyze and redesign the front bumper structure to absorb impact energy effectively during vehicle–pedestrian collisions. Specifically, it evaluates:

- The geometry (profile) of the front bumper,

- The material composition, and

- The thickness optimization using advanced simulation tools such as HyperMesh and LS-DYNA.

Methodology

The research used the Toyota Camry finite element model and the V-THUMS pedestrian simulation model to replicate realistic collision conditions at 40 km/h. The study assessed several biomechanical injury indices — including bending moment, resultant force, and stress distribution — across the femur, tibia, and knee joints.

Three key factors were optimized:

- Profile: Comparing original vs. two redesigned shapes.

- Thickness: Testing levels of 2.0 mm, 2.5 mm, 3.0 mm, and 4.0 mm.

- Material: Evaluating polymers (PC, PP-TD20, PCABS) and metals (A3003 aluminum, SAPH440 steel).

Findings

Simulation results revealed:

- The Shape 2 bumper profile significantly reduced bending moments and resultant forces on pedestrians’ lower limbs.

- An optimal thickness of 2.5 mm achieved the best balance between impact absorption and structural integrity.

- Among materials tested, PP-TD20 plastic showed superior performance in reducing both bending and total forces while maintaining durability.

Impact Distribution

Comparative analysis of von-Mises stress distributions indicated that the optimized bumper reduced concentrated stress on the tibia region during collisions. Additionally, ligament rupture simulations demonstrated that the improved bumper design lowered the probability of knee ligament failures by 25–30%.

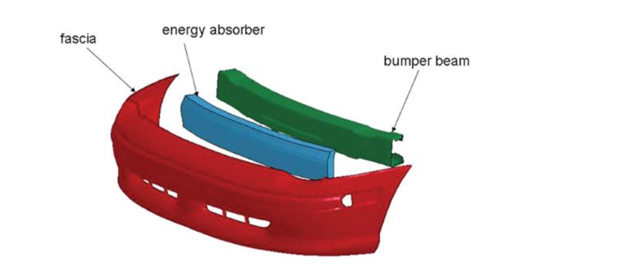

Figure 1: Basic structure of car front bumper

Figure 1: Basic structure of car front bumper

Conclusion

This research highlights the potential of finite element-based optimization in improving pedestrian safety. The optimized bumper design—featuring a 2.5 mm PP-TD20 structure—provides a viable approach to reducing leg injuries by over 20%, offering new design guidelines for automakers.