1. Functions of the Suspension System

The suspension system in automotives serves the following primary functions:

- Shock Absorption and Vibration Damping: It absorbs and eliminates vibrations from the road surface, providing a smooth and comfortable experience for passengers.

- Ensuring Road Grip: It ensures that the wheels maintain good contact with the road, enhancing road grip and stability when the vehicle turns, brakes suddenly, or accelerates.

- Protecting the Chassis and Other Components: It minimizes the impact of forces from the road surface on the chassis and other vehicle parts, helping to extend the vehicle's lifespan.

- Enhancing Vehicle Control: It improves the driver's ability to control the vehicle, particularly when driving on rough terrain or in extreme weather conditions.

2. Components and Details of the Automotives Suspension System

The basic structure of an automotives's suspension system consists of three main components. Below, we will help you explore these parts in detail to better understand the suspension system in your vehicle.

- Spring: The primary elastic component, capable of deforming to absorb energy from vibrations.

- Shock Absorber: A hydraulic or pneumatic component that converts the kinetic energy of vibrations into thermal energy, reducing shock and stabilizing the vehicle.

- Stabilizer Bar: A metal bar connecting two wheels on the same axle, reducing body roll when turning.

- Bushing: A component made of rubber or polyurethane that connects various suspension parts to the chassis, reducing noise and vibration.

- Wheels and Tires: The wheels and tires also play a role in the suspension system, absorbing some of the vibrations from the road.

3. Operation Principle of the Automotives Suspension System

Fundamentally, the suspension system operates through the interaction of parts such as springs, shock absorbers, and control arms. When the vehicle moves over an uneven surface, the wheels directly interact with rough patches of road, generating vibrations. At this point, the springs compress and absorb these vibrations. Next, the shock absorber controls the rebound of the springs, preventing the vehicle from bouncing excessively. Simultaneously, the control arms and stabilizer bar ensure the wheels remain vertical to the vehicle's frame, reducing the risk of rollover.

Source: internet

3.1 For Independent Suspension Systems

In the case where the left wheel of the vehicle is impacted by a rough patch of road, the independent suspension system ensures no connection between the two wheels. Therefore, the upward motion of the left wheel will not affect the right wheel.

The force from the road is absorbed by the spring and shock absorber, which are connected to the main frame, thus minimizing the impact. The stiffness of the spring and shock absorber maintains the friction between the wheel and the road, ensuring vehicle balance and stability.

This is a more advanced suspension system, typically used in modern vehicles. Although it is more expensive and involves more components, it offers greater comfort and stability.

The Independent Suspension System Works as Its Name Suggests

The Independent Suspension System Works as Its Name Suggests

3.2 For Semi-Independent/Dependent/Equalizing Suspension Systems

Other suspension systems, apart from independent ones, include semi-independent, dependent, and equalizing types. In the case where the left wheel is impacted, as explained in the independent suspension system, the pair of wheels connected through a solid axle or live axle with leaf springs will both be affected.

As a result, if the left wheel is impacted, the right wheel will also bear the force from the road. Meanwhile, the leaf springs will stretch and absorb the shock from both wheels. This suspension system is commonly used in commercial vehicles due to its sturdiness and lower cost compared to independent suspension. Its drawback, of course, is that it is less comfortable and not as smooth as independent suspension.

4. Common Types of Suspension Systems in Automotives

There are many types of suspension systems available in the market today. To differentiate them, the following classifications can be made:

- Dependent Suspension System

- Independent Suspension System

- Semi-Active and Active Suspension System

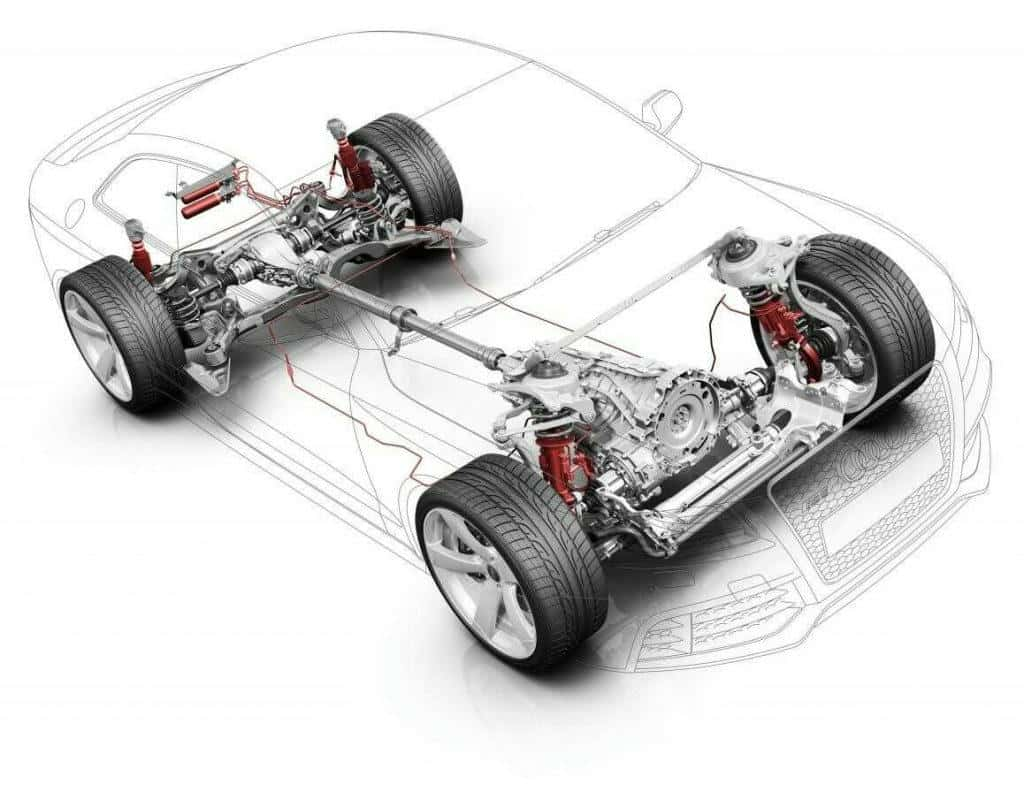

4.1 The Independent Suspension System

The Independent Suspension System allows each wheel to move up and down independently from the other wheels on the same axle. This helps minimize the impact of road vibrations on the vehicle's body, enhancing road grip and control during turns.

Source: internet

Source: internet

The Independent Suspension System allows each wheel to move up and down independently from the other wheels on the same axle.

Structure

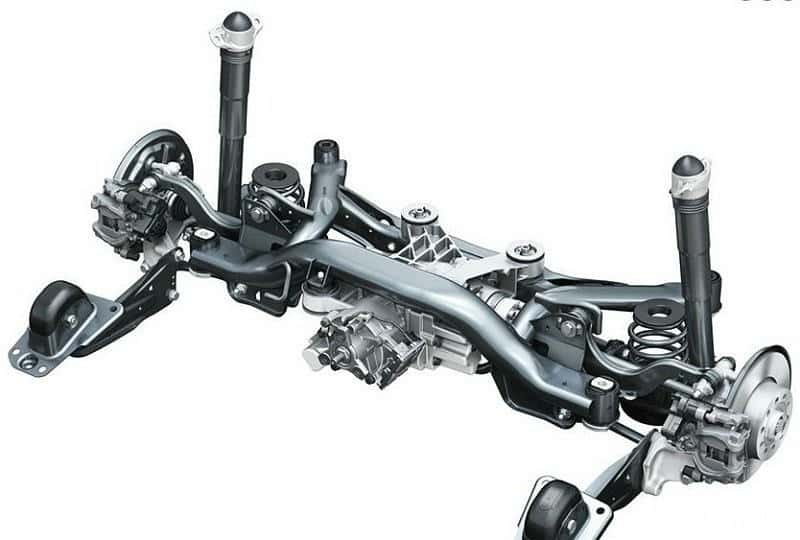

The Independent Suspension System typically includes the following main components:

- Control Arms: One or more control arms (typically upper and lower control arms) that connect the wheel to the vehicle's frame.

- Coil Spring: The primary elastic component that absorbs and stores energy from vibrations.

- Shock Absorber: A hydraulic or pneumatic component that converts the kinetic energy of vibrations into thermal energy, helping to reduce shock and stabilize the vehicle.

- Stabilizer Bar: A metal bar that connects the two wheels on the same axle, helping to reduce body roll during turns.

- Bushing: A rubber or polyurethane component that connects various suspension parts to each other and to the chassis, helping to reduce noise and vibration.

Operating Principle

When a wheel encounters an obstacle, the spring compresses and absorbs the energy from the vibrations. The shock absorber then converts this kinetic energy into heat, helping to reduce shock and stabilize the vehicle. Since each wheel is independently suspended, the movement of one wheel has a minimal impact on the other, leading to smoother and more stable vehicle operation.

Advantages

- Greater Comfort: Since each wheel moves independently, the independent suspension system absorbs road vibrations more effectively, providing a smoother and more comfortable driving experience compared to dependent suspension systems.

- Increased Flexibility: Each wheel can adapt independently to the terrain, improving road grip, especially when turning or navigating obstacles.

- Improved Handling: Reduces body roll during turns, helping the vehicle remain stable and easier to control.

- Weight Reduction: Independent suspension systems are generally lighter than dependent systems, which improve performance and fuel efficiency.

Disadvantages

- More Complex Design: Independent suspension systems have more components, making them more complex and requiring higher maintenance expertise.

- Higher Cost: Due to the complex design, the production and maintenance costs of independent suspension systems are generally higher than those of dependent systems.

- Less Durability: The joints and small components in the independent suspension system are more prone to wear and damage than those in dependent systems.

Common Types of Independent Suspension Systems

- MacPherson Suspension: A simple, compact design, low cost, easy to maintain, commonly found in small to medium-sized passenger cars.

- Double Wishbone Suspension: Offers better wheel control, greater stability during turns, and high road grip, typically used in sports cars, luxury vehicles, and racing cars.

- Multi-Link Suspension: Provides the best comfort and stability, offering flexible adjustments for various vehicle types and operating conditions, commonly found in luxury and high-performance vehicles.

Dependent Suspension System

A dependent suspension system connects two wheels on the same axle using a rigid axle or beam. When one wheel moves up or down, the other wheel is also affected and moves in unison.

Source: internet

Source: internet

Dependent suspension is a type of suspension where two wheels with the same axle are connected by a rigid shaft or beam.

Structure

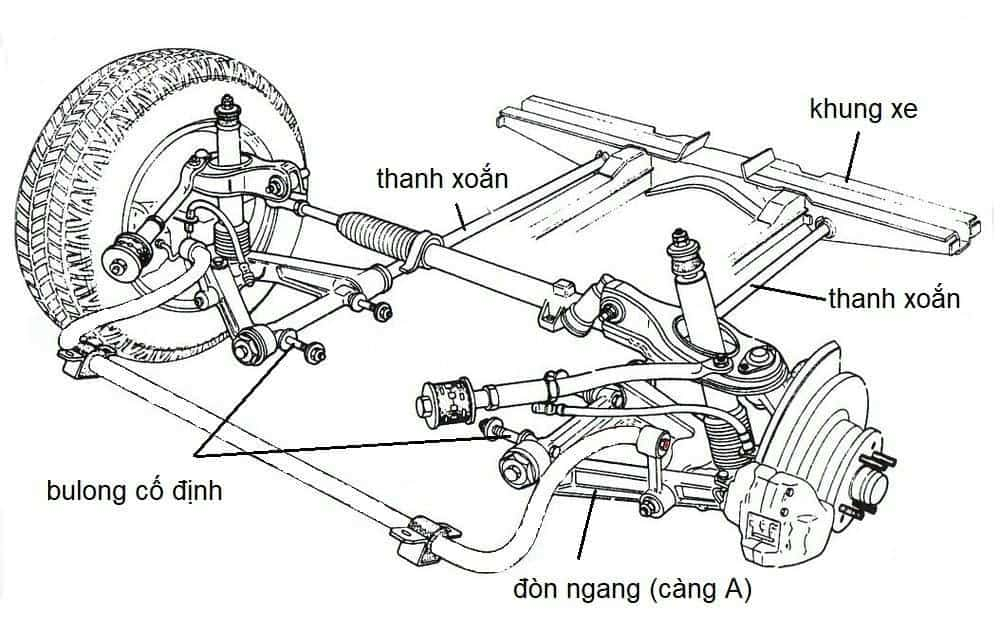

A dependent suspension system consists of the following main components:

- Solid Axle: A rigid axle that connects the two wheels, ensuring they remain parallel and at a fixed distance.

- Leaf Spring: The primary elastic component that bears the load and absorbs vibrations from the road surface.

- Torsion Bar: Another elastic component, often used in smaller passenger vehicles.

- Panhard Bar: A metal bar that connects the solid axle to the vehicle's frame, maintaining the axle's horizontal position.

- Shock Absorber: Hydraulic or pneumatic shock absorbers that help eliminate road vibrations, improving ride comfort.

- Coil Spring: An additional elastic component, often used with leaf springs or torsion bars to enhance shock absorption.

Operating Principle

When a wheel passes over a pothole or speed bump, the leaf spring or torsion bar bends and absorbs the energy from the vibrations. The shock absorber then converts this kinetic energy into thermal energy, reducing shock and stabilizing the vehicle. The Panhard bar ensures the solid axle remains parallel to the chassis, maintaining stability during turns.

Advantages

- Simple Structure: Fewer complex components, making it easier to manufacture, maintain, and repair, thus reducing costs.

- Lower Cost: Due to the simple design, production and maintenance costs are lower compared to independent suspension systems.

- High Load-Bearing Capacity: Suitable for trucks, pickups, and heavy-duty vehicles.

- Durability: Fewer moving parts reduce the risk of damage, leading to greater longevity in harsh conditions.

- Stability During Turns: Minimizes body roll when turning, especially when the vehicle is carrying heavy loads.

Disadvantages

- Less Comfort: Since the two wheels on the same axle are linked, the movement of one wheel affects the other, leading to stronger shocks and vibrations compared to independent suspension systems.

- Limited Flexibility: The system does not allow each wheel to adapt independently to the terrain, which reduces road grip and handling, especially during high-speed turns.

- Difficult to Adjust: Adjusting the stiffness of the dependent suspension system is generally more challenging than with independent suspension systems.

Active and Semi-Active Suspension Systems

Active and semi-active suspension systems are advanced technologies that provide superior control and comfort for vehicles. Some common systems on the market today include:

Air Suspension

- Structure: Uses air bags instead of traditional steel springs.

- Advantages: Allows adjustment of vehicle ride height, providing optimal comfort.

- Disadvantages: High cost, complexity, requires frequent maintenance.

- Application: Commonly used in luxury vehicles and high-end off-road vehicles.

Hydraulic Suspension

- Structure: Uses hydraulic fluid to control the stiffness of the shock absorbers.

- Advantages: Quickly adapts to road surface changes, providing excellent comfort and stability.

- Disadvantages: High cost, complexity.

- Application: Commonly used in luxury and sports vehicles.

Electronic Suspension

- Structure: Integrates sensors and electronic controllers to continuously adjust shock absorber force and spring stiffness.

- Advantages: Optimizes comfort and stability under all operating conditions.

- Disadvantages: High cost, complexity.

- Application: Commonly used in luxury and sports vehicles.

Comparison of Popular Suspension Systems

| Suspension Type | Advantages | Disadvantages | Common Applications |

| Dependent | Simple structure, low cost, good load-bearing capacity, high durability, stable during turns | Less comfort, limited flexibility, hard to adjust | Trucks, pickups, off-road vehicles |

| Independent (MacPherson) | Simple, compact, low cost, easy to maintain | Lower load-bearing capacity than other independent types | Small to medium-sized passenger cars |

| Independent (Double Wishbone) | Better wheel control, stable during turns, high road grip | Complex structure, high cost | Sports cars, luxury vehicles, racing cars |

| Independent (Multi-Link) | Superior comfort and stability, flexible adjustment | Most complex structure, highest cost | Luxury, high-performance vehicles |

| Semi-Active/Active | Optimal comfort, self-adjusting, adapts to any terrain | Very high cost, complex | Luxury vehicles, high-performance vehicles |