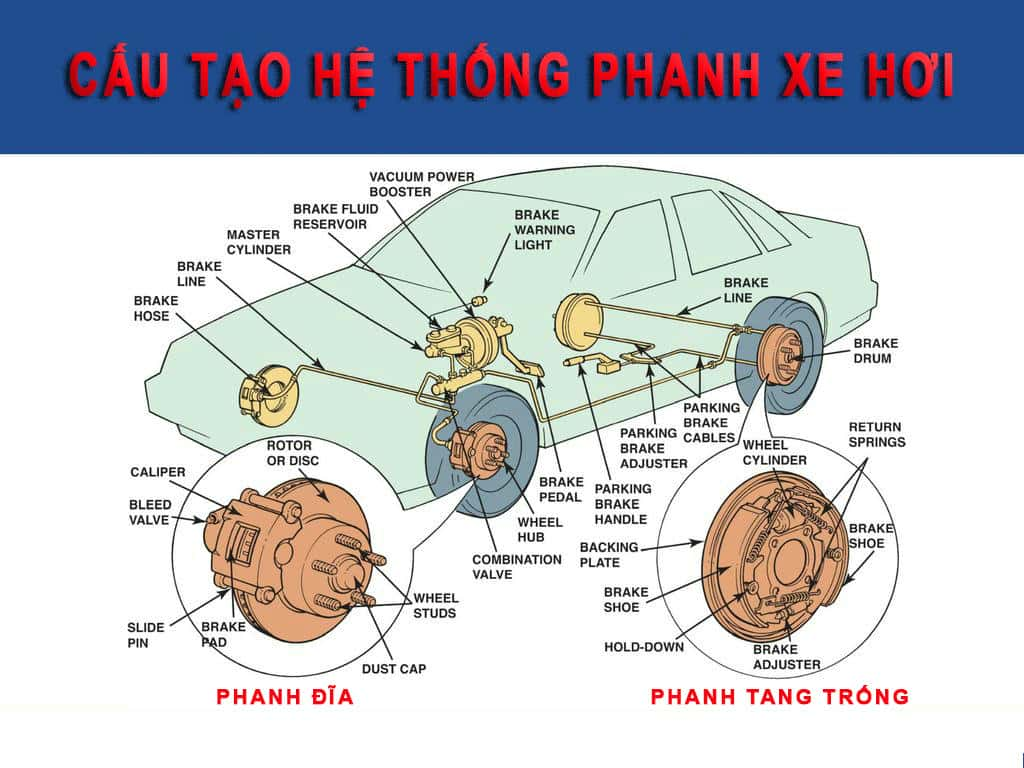

- Overview of the Brake System

(Source: Internet)

(Source: Internet)

- Function, Requirements, and Classification of the Brake System.

1.1 - Function

The brake system in a car is used to rapidly reduce the vehicle's speed or stop the car in an emergency. It also ensures that the vehicle remains securely parked and does not roll, even on an incline. With the brake system, the driver can operate the vehicle safely at high speeds, thus enhancing transport efficiency and vehicle performance.

Typically, two independent brake systems are installed: the foot brake (operated by a foot pedal) and the hand brake (operated by a manual lever). The hand brake often features a locking mechanism that allows the vehicle to remain stationary without the need to hold the lever, while the foot brake only operates when the pedal is pressed and is released when the foot is lifted. The foot brake typically uses a wheel braking mechanism, while the hand brake employs a drive shaft braking mechanism.

1.2 - Requirements

The brake system must meet the following criteria:

- Provide maximum braking efficiency on all wheels, ensuring a short stopping distance in emergency situations.

- Operate smoothly in all circumstances to maintain the stability of the vehicle.

- Feature light control, meaning the force applied to the brake pedal or lever should not be excessive.

- The braking mechanism should be highly responsive.

- Ensure proper distribution of braking torque across all wheels, utilizing the full contact weight during braking under any intensity.

- Prevent brake self-engagement.

- The braking system should dissipate heat effectively.

- The coefficient of friction between the brake pads and drums should be high and stable under normal usage conditions.

- Maintain a proportional relationship between the force applied to the pedal or lever and the braking force on the wheels.

- The system should be capable of sustaining long-term use.

- It must ensure the car can stop in any situation. In an emergency stop, the vehicle should halt in the shortest possible distance, achieving maximum deceleration. According to European standards, a passenger car must perform optimally in all test scenarios.

- For foot brakes, at a starting speed of 80 km/h, the stopping distance must be less than 50.7 meters, with a braking acceleration greater than 5.8 m/s² and the maximum braking force applied to the foot pedal being 50 kg.

- The brake system must be highly sensitive, with minimal variation in braking efficiency between different stops.

- Prevent wheel slippage on the road.

- The foot and hand brakes must operate independently without affecting each other. The hand brake can serve as a backup in case of a foot brake failure, ensuring emergency functionality.

- The hand brake must hold the vehicle in place, even on an incline of at least 18% (16-20 degrees).

- The brake components should dissipate heat effectively without transferring heat to surrounding parts (e.g., tires, hubs) and should be easily adjustable for replacing damaged parts.

Additionally, the system must be compact, lightweight, durable, and meet general mechanical structure requirements.

1.3 - Classification

1.3.1 - Classification by Function

- Main brake system.

- Parking brake system.

- Backup brake system.

- Gradual braking system (engine, hydraulic, or electronic braking).

To better understand engine braking: When the car is moving, the accelerator is released to allow the engine to operate in idle mode. The inertia and friction within the system slow the vehicle. This method is called engine braking. When descending steep slopes or driving on slippery roads, engine braking should be employed. The lower the gear, the more effective the braking.

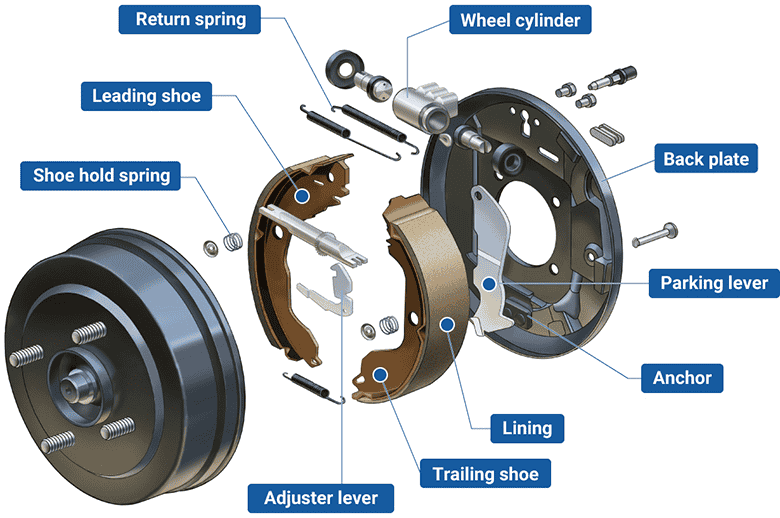

1.3.2 - Classification by Brake Mechanism

- Brake system with drum brake mechanism.

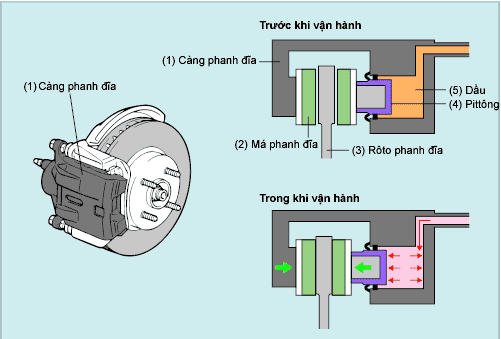

- Brake system with disc brake mechanism.

(Source: Internet)

(Source: Internet)

Disc brake mechanism

1.3.3 - Classification by Brake Actuation

- Mechanically actuated brake system.

- Hydraulic brake system.

- Pneumatic brake system.

- Vacuum-assisted or pneumatic brake system.

- Boosted brake actuation system.

- Electrically actuated brake system.

1.3.4 - Classification by Brake Torque Adjustment Mechanism

Brake system with a brake force distribution mechanism.

1.3.5 - Classification by Anti-lock Braking Capability

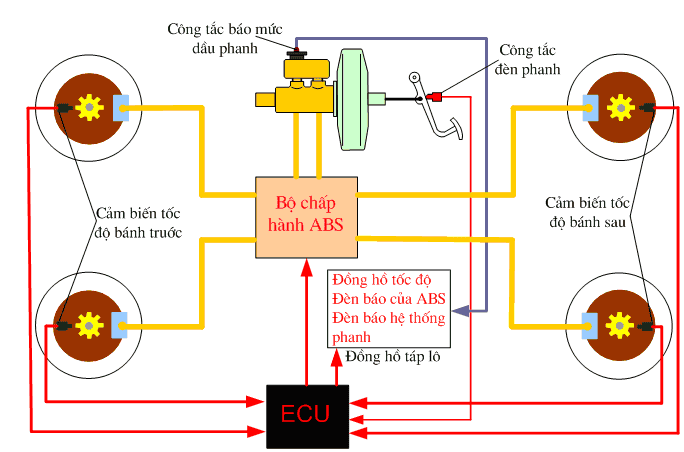

According to the ability to prevent wheel locking when braking, we have a braking system with anti-lock braking system (ABS braking system).

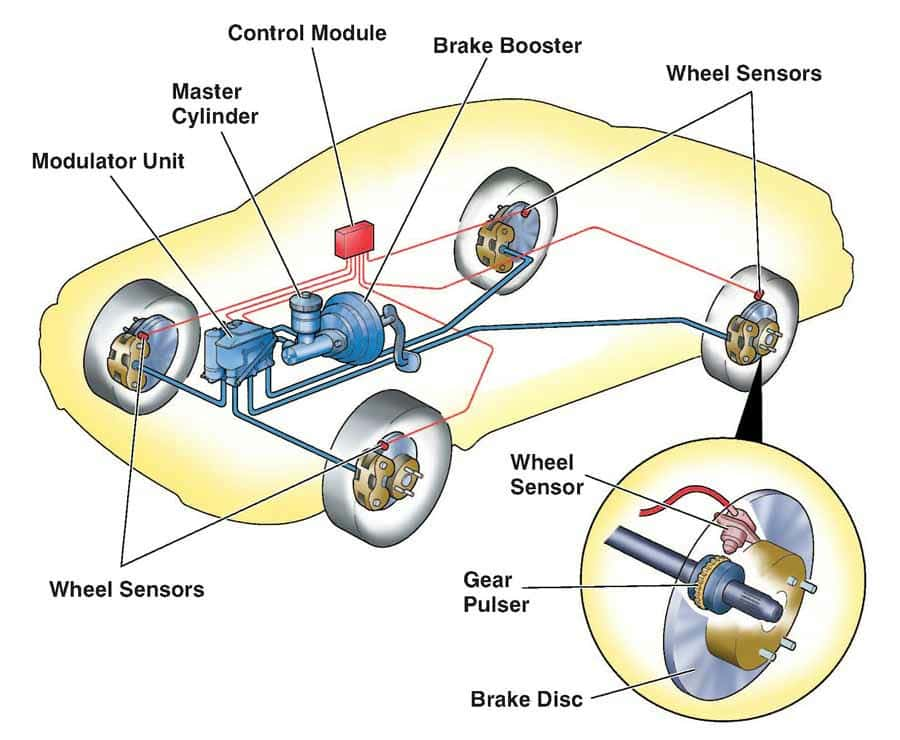

ABS brake sensor and signal layout diagram (Source: Internet)

ABS brake sensor and signal layout diagram (Source: Internet)

The foot brake is the primary braking system in passenger vehicles, while the hand brake serves as a backup. The control systems of both are independent, reliable, and the hand brake must feature a self-locking mechanism to avoid constant manual engagement.

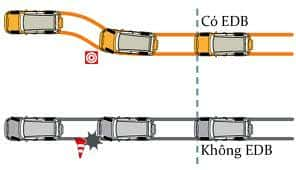

- Electronic Brakeforce Distribution (EBD) System.

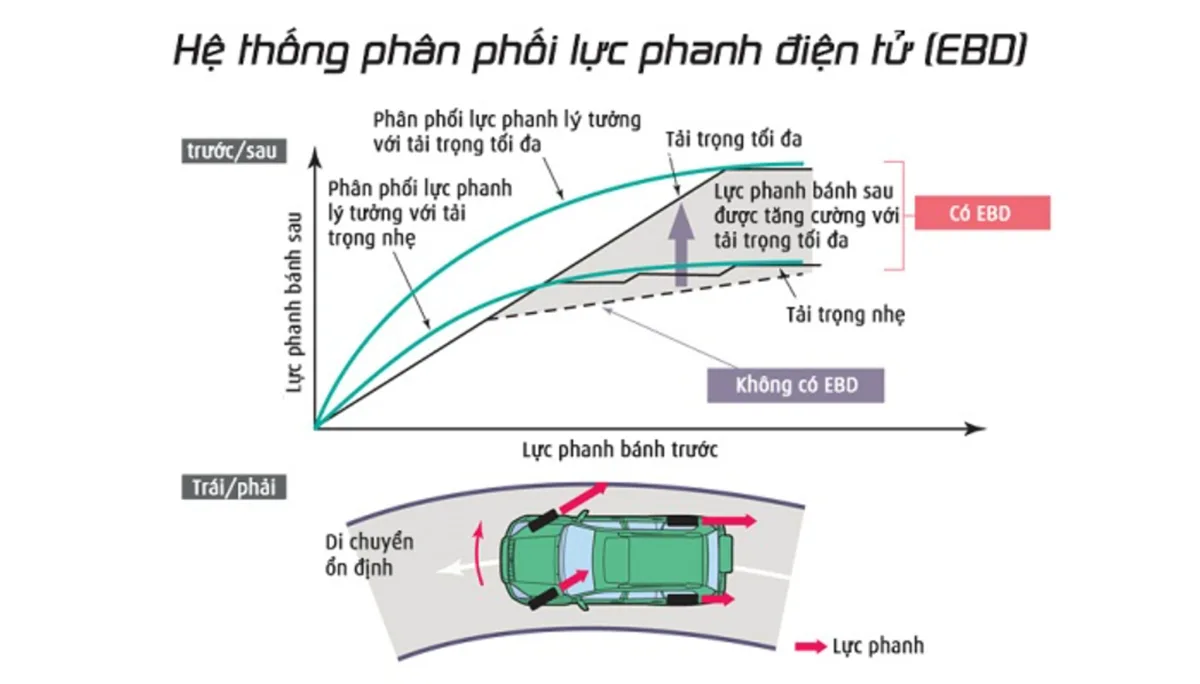

The Electronic Brakeforce Distribution (EBD) system helps distribute braking force in proportion to the load acting on the brake system, preventing wheel slippage and reducing the stopping distance.

Source: Internet

Source: Internet

The Electronic Brakeforce Distribution (EBD) system is a technology that works alongside the Anti-lock Braking System (ABS) and the Brake Assist (BA) system, becoming standard safety features in modern cars. These technologies help reduce accidents in emergency braking situations.

The EBD system operates on the principle that braking efficiency is maximized when the braking force applied to each wheel corresponds to the load on that wheel. This principle guides the operation of the Emergency Brake Distribution (EBD) system.

Source: Internet

Source: Internet

In an emergency braking situation, the weight of the vehicle is transferred forward due to inertia, and most vehicles have engines located at the front. As a result, the front wheels bear a significant load during rapid braking. To optimize braking, manufacturers calculate the distribution of braking force, applying more to the front wheels than to the rear ones for safety. However, this mechanical distribution method is only effective during emergency braking on straight roads. On curves or when cornering, the load distribution shifts, and emergency braking in such conditions can be unsafe.

To ensure safety under various road conditions and load variations, the Electronic Brakeforce Distribution (EBD) system automatically adjusts the braking force distribution across each wheel based on real-time electronic calculations, replacing the previous mechanical distribution system.

Source: Internet

Source: Internet

With sensors placed on all four wheels, in an emergency braking situation, the sensors detect changes in load and braking force on each wheel, sending signals to the central control unit. This unit then calculates and distributes the appropriate brake fluid pressure to each wheel, ensuring the braking force matches the load, enhancing safety for the driver.

In automotives, the EBD system, along with ABS, is one of the most effective safety features for optimal braking. The ABS prevents the wheels from locking by modulating brake pressure, reducing wheel slippage, and allowing the driver to maintain steering control, while the EBD system adjusts the braking pressure across each wheel for safe operation.